Applications:Aggregate field,concrete mixing plant,dry mortar plant desulfurization,quartz sand,etc.

Materials:barite, marble, talcum, calcite, dolomite, fluorite, kaoline, coal, gypsum.

Feed size:13-369mm

Capacity:1-1270t/h

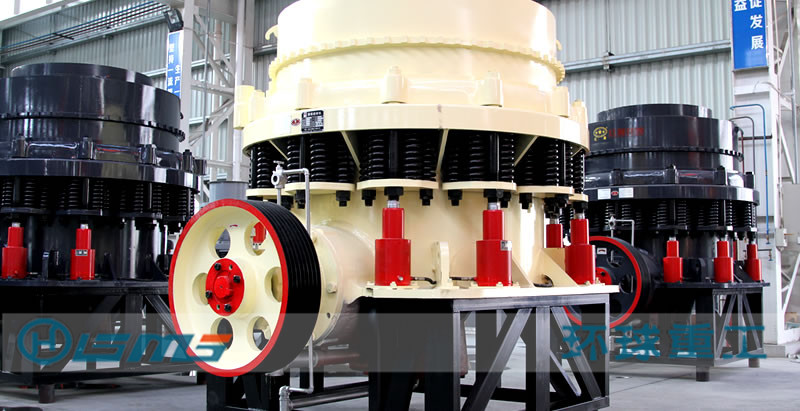

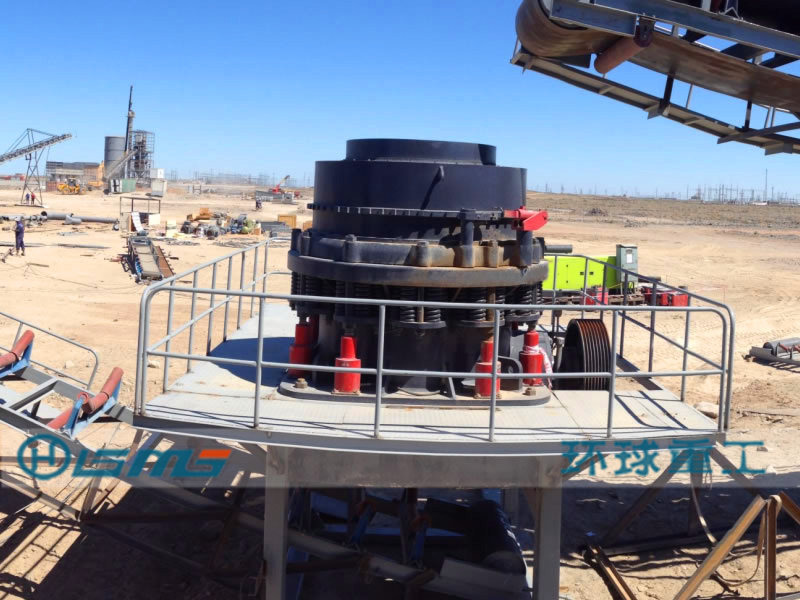

As the second crushing process, CS High-Efficiency Cone Crusher can process river stone, granite, basalt and ironstone for medium crushing. This machine takes advantages of safety and easy maintenance, and its overload protection device can make the production stable and steady.

CS Series Cone Crusher is the earliest cone crusher, and also the most widely used cone crusher in the world today. The improved and refined CS Series Cone Crusher owns a more reasonable structure and more advanced technocal parameters. China cone crusher has excellent performance in manufacturing, installation, use and maintenance.

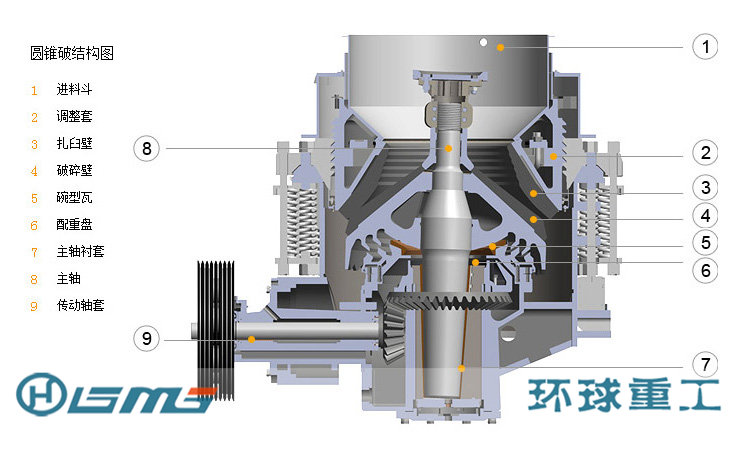

CS Series Cone Crusher is widely applied in cement making industry, building, sand making, metallurgical industry, etc.It is suitable for both metallic minerals and non-metallic minerals, such as iron ore, nonferrous metal ore, granite, limestone, quartzite, sandstone, pebble, etc. Illustration of How CS Series Cone Crusher crush through a horizontal axle and a pair of bevel gear, the motor drives the eccentric sleeve to revolve. The revolution of the eccentric sleeve makes the mantle move towards to the bowl liner from time to time. In this way, the ores and rocks will be pressed and finally crushed.

1. The cone crusher is of high performance

2. High stability and reliablity if you choose cone crusher expert

3. Easy cavity dumping

4. Easy maintenance and easy operation

5. Low cost and wide application for China cone crusher

Global Heavy Industry provides customers with production line design process and helps to design a satisfactory and reasonable production line. We also provide related technical personnel training and enable them to acquire a certain amount of technical knowledge and machine maintenance tips.

| Specification | Model | Diameter of large end of crushing cone (mm) |

Max.feeding size(mm) |

Width of discharge opening (mm) |

Processing capacity (t/h) |

Motor power (kw) |

Total weight (t) |

Dimensions (L×W×H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910×2894×3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622×3302×4470 |

Models and specifications of the equipment, according to the actual needs of customers, or special requirements of customers, can be custom designed.